Shoring Up Supply Chain Demand by Reshoring

Leave a Comment Although reshoring has been a hot topic over the last several years, the conversations have become even more serious as a result of the pandemic, and the significant supply chain disruptions caused by Covid that have occurred in the past two years. Lockdowns, skyrocketing freight costs, port congestion and long lead times have caused major headaches. As a result, reshoring is one mitigation strategy that manufacturers are employing to reduce supply chain risk, especially in light of the potential for continued disruptions. For those reasons and more, many customers have begun sourcing production domestically again. D&M has been ready to help.

Although reshoring has been a hot topic over the last several years, the conversations have become even more serious as a result of the pandemic, and the significant supply chain disruptions caused by Covid that have occurred in the past two years. Lockdowns, skyrocketing freight costs, port congestion and long lead times have caused major headaches. As a result, reshoring is one mitigation strategy that manufacturers are employing to reduce supply chain risk, especially in light of the potential for continued disruptions. For those reasons and more, many customers have begun sourcing production domestically again. D&M has been ready to help.

The situation is volatile and changing practically day to day. Right now, parts of China are still under lockdown to control the spread of Covid, a strategy that has been implemented in almost every major city as Covid cases increase. Areas covering roughly 30% of China’s GDP were affected by the outbreaks, according to Goldman Sachs Group Inc. And even while some of the lockdowns have eased recently and then have been reinstated when Covid reappears, ports have been at a virtual standstill and overall manufacturing production has been severely impacted with long lead times causing huge delays. In addition to delays, there are often quality concerns, and issues of traceability, especially in the instance of medical parts manufacturing.

Additionally, freight costs from China to the U.S. have also been volatile. According to Freightos, costs during the second week of June 2022 were at $9,585 per 40-foot container to the West Coast from East Asia. Those numbers have come down 57% from the peak of $22,173 in September 2020, but it is still up more than three-fold from $2,700 at the pandemic start.

Not only have freight costs increased, the processing and transit times to get a container out of China is currently double what it was just a few months ago. That doesn’t include the time to get it processed in the U.S. — only the time from a manufacturer’s dock in China to making a landing at a U.S. port.

Many manufacturers have historically not considered the full landed costs of offshoring their production. They have focused on direct manufacturing costs and transportation costs but have not considered end-to-end production costs and risks. Although part costs may be lower, total offshore production costs are often higher, and when supply chain risks are factored in, the costs become an order of magnitude higher.

The current situation has changed the calculus. Many domestic businesses are experiencing both the costs and the risks of manufacturing offshore. These companies are looking to reshore or near-shore operations to mitigate these issues. We have been able to help.

Many of our customers are moving programs from overseas and only considering domestic suppliers for new programs. If you’re looking for a new resource to help reshore your manufacturing, look to D&M.

Find out why our customers have sourced their parts right here in the U.S. since our inception 50 years ago. Let us quote your next project and learn how we can help you bring your manufacturing stateside again.

All my best,

Chip

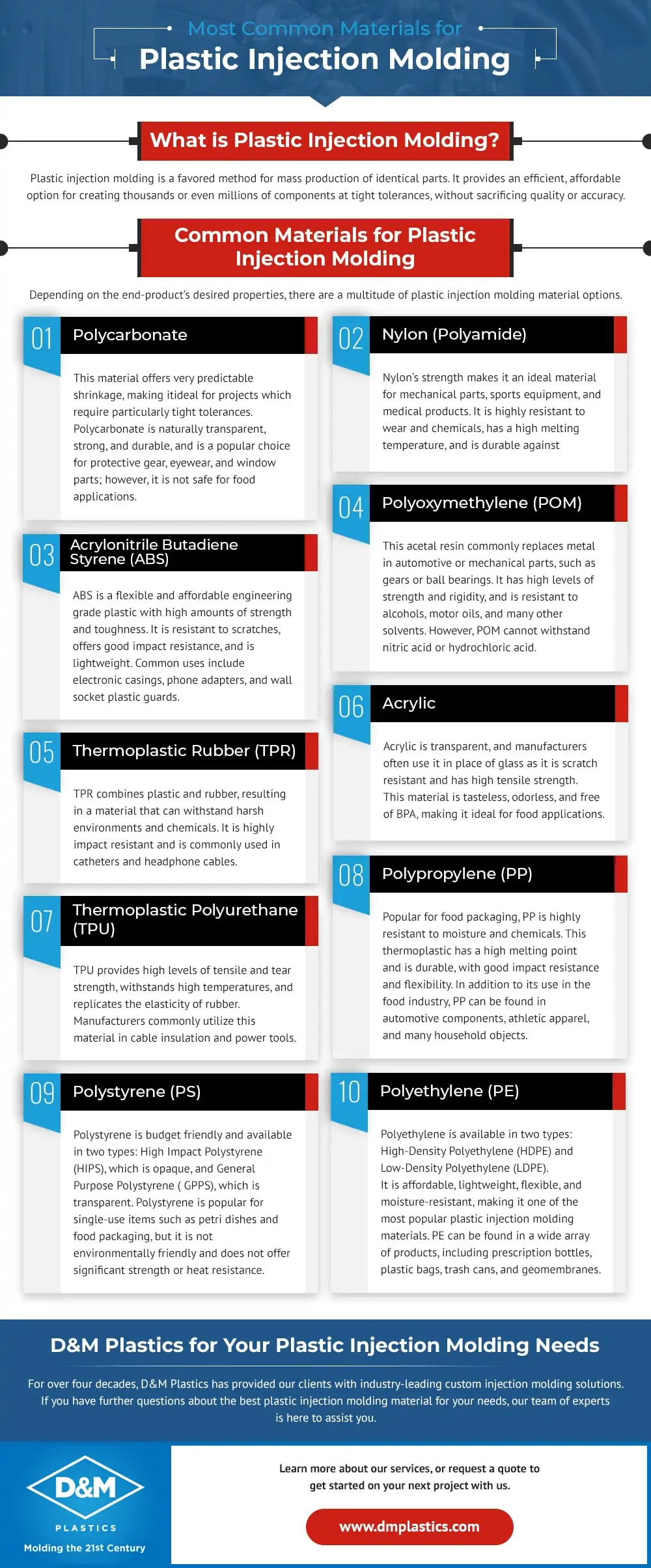

Most Common Materials for Plastic Injection Molding

Leave a CommentAt D&M Plastics, we specialize in performing high-volume injection molding using state-of-the-art equipment and technology to create tight-tolerance precision parts down to 0.001 inches. Our capabilities include:

- Clean Room Injection Molding

- Tight Tolerance Molding

- In-Mold Labeling

- Insert Molding

We also offer many value-added and secondary services, full service support, and real-time production analysis.

Common Materials for Plastic Injection Molding

Common Materials for Plastic Injection Molding

Depending on the end-product’s desired properties, there are a multitude of plastic injection molding material options.

Polycarbonate

This material offers very predictable shrinkage, making it ideal for projects which require particularly tight tolerances. Polycarbonate is naturally transparent, strong, and durable, and is a popular choice for protective gear, eyewear, and window parts; however, it is not safe for food applications.

Nylon (Polyamide)

Nylon’s strength makes it an ideal material for mechanical parts, sports equipment, and medical products. It is highly resistant to wear and chemicals, has a high melting temperature, and is durable against impacts.

Acrylic

Acrylic is transparent, and manufacturers often use it in place of glass as it is scratch resistant and has high tensile strength. This material is tasteless, odorless, and free of BPA, making it ideal for food applications.

Polyoxymethylene (POM)

This acetal resin commonly replaces metal in automotive or mechanical parts, such as gears or ball bearings. It has high levels of strength and rigidity, and is resistant to alcohols, motor oils, and many other solvents. However, POM cannot withstand nitric acid or hydrochloric acid.

Polystyrene (PS)

Polystyrene is budget friendly and available in two types: High Impact Polystyrene (HIPS), which is opaque, and General Purpose Polystyrene (GPPS), which is transparent. Polystyrene is popular for single-use items such as petri dishes and food packaging, but it is not environmentally friendly and does not offer significant strength or heat resistance.

Acrylonitrile Butadiene Styrene (ABS)

ABS is a flexible and affordable engineering grade plastic with high amounts of strength and toughness. It is resistant to scratches, offers good impact resistance, and is lightweight. Common uses include electronic casings, phone adapters, and wall socket plastic guards.

Polypropylene (PP)

Popular for food packaging, PP is highly resistant to moisture and chemicals. This thermoplastic has a high melting point and is durable, with good impact resistance and flexibility. In addition to its use in the food industry, PP can be found in automotive components, athletic apparel, and many household objects.

Polyethylene (PE)

Polyethylene is available in two types: High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE). It is affordable, lightweight, flexible, and moisture-resistant, making it one of the most popular plastic injection molding materials. PE can be found in a wide array of products, including prescription bottles, plastic bags, trash cans, and geomembranes.

Thermoplastic Polyurethane (TPU)

TPU provides high levels of tensile and tear strength, withstands high temperatures, and replicates the elasticity of rubber. Manufacturers commonly utilize this material in cable insulation and power tools.

Thermoplastic Rubber (TPR)

TPR combines plastic and rubber, resulting in a material that can withstand harsh environments and chemicals. It is highly impact resistant and is commonly used in catheters and headphone cables.

D&M Plastics for Your Plastic Injection Molding Needs

For over four decades, D&M Plastics has provided our clients with industry-leading custom injection molding solutions. If you have further questions about the best plastic injection molding material for your needs, our team of experts is here to assist you. Learn more about our services, or request a quote to get started on your next project with us.