Molding Services You Can Count On

At D&M Plastics, we are injection molding experts with over 50 years of experience working with plastics. Our team is dedicated to quality and outstanding service for every customer.

D&M Plastics’ Injection Molding Capabilities

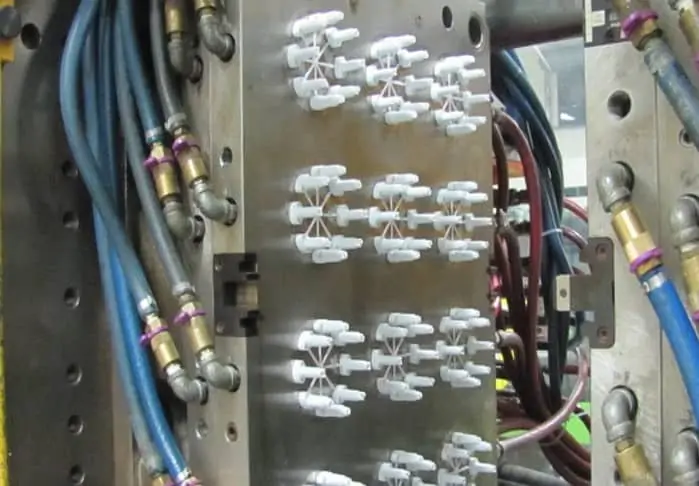

We offer comprehensive injection molding services to meet the requirements of nearly any application or industry, including achieving tight tolerances and high-quality parts. We are ISO 9001:2015 and ISO 13485:2016 certified, and maintain an external defect rate of just 17 PPM.

Our facility has a fully loaded onsite tool room to ensure high-quality molded production runs. Maintaining and repairing tools keeps them in pristine condition and enables us to extend their lifespan, some of which have been running for over 20 years. Our quality assurance department uses state-of-the-art metrology equipment to ensure that our products’ precision and accuracy mirrors the efficiency of our production program. With our broad expertise and top-of-the-line presses (rated at 40–400 tons), we injection mold parts vertically, horizontally, and at 45 degrees using an extensive range of high-performance plastics.

To ensure that we meet our clients’ needs, we’ve implemented rigorous materials management that includes attention to humidity, material density, and mix ratios. Additionally, we perform internal inspections every two hours while running production. As a result, we’re able to meet customer specifications for function, strength, durability, and color. Our manufacturing capabilities extend beyond cleanroom molding to overmolding, insert molding, and in-molding labeling (IML). We’re experienced with producing multicomponent parts with Class A surfaces that have complex geometries as well as undercuts and thin wall stock. We easily uphold tolerances as close as ±0.001”.

Additional Molding Capabilities

In addition to standard injection molding, we offer these capabilities:

- Cleanroom molding. Our facility includes an ISO Class 8 cleanroom for injection molded parts requiring high levels of technical cleanliness, such as medical, food and beverage, electronics, and pharmaceutical applications.

- Insert molding. With this single-shot process, we can inject plastic over a metallic component within a mold to create a single item from two different materials.

- Overmolding. In overmolding, two shots of molten plastic are injected sequentially. The first shot involves injecting the substrate or core material. This could be a pre-manufactured component like a metal insert, a plastic part, or even a foam. The second shot then overmolds the substrate by injecting a second type of plastic around it. This creates a single, integrated part with the substrate embedded within the overmolded material.

Our Equipment

Our facilities are equipped to handle high-volume, rapid production that meets your requirements. We operate more than 30 presses that range from 40 to 400 tons to achieve the precise specifications needed for each project. We also operate an extensive on-site tool and CNC machine room for press maintenance, mold repair, and value-added services such as machining and creating your proprietary or other requested finishes.

Materials

Many different plastics and polymers are compatible with injection molding. This makes it an excellent choice for parts with all kinds of specifications including high and low-temperature resistance, chemical and corrosion resistance, high strength, light weight, and more.

Some common materials for injection molding include, but are not limited to:

- Acrylonitrile butadiene styrene (ABS)

- Polycarbonate copolymer acrylonitrile butadiene styrene (PC ABS)

- Liquid-crystal polymer (LCP)

- Acrylic (PMMA)

- Nylon

- Polypropylene (PP)

- Polystyrene (PS)

- Polyethylene (PE)

Learn more about material properties and selection in our materials guide.

Industries Served

We provide injection molding for applications across a range of industries, including:

-

Medical

We work with customers in the medical industry to create parts and components for medical devices like handhelds, single-use components, and respiratory connectors. We also manufacture medical and dental plastic parts, such as housings, vials, dental equipment, and allergy testing components. ISO Class 8 clean room injection molding is available for these and other applications.

-

Electronics

Electronic injection molded components include high-precision items like electronic connectors, housings, telecommunications parts, sensors and other testing equipment, and semiconductor components.

-

Automotive

We have manufactured a variety of automotive parts such as interior knobs, assemblies, and much more. We can produce multi-component parts with Class A surfaces, complex geometries, undercuts, and thin walls and easily uphold tolerances as small as ±0.001 in. PPAP documentation is consistently accurate and submitted on time as well.

-

Defense & Military

Many parts used in defense and military equipment must meet precise specifications and weight requirements. We can meet these needs with injection molding for different types of aircraft interior and engine components, using engineered specialty plastics including PEEK and ULTEM.

Advantages of Our Injection Molding Services

At D&M Plastics, injection molding has several key benefits, including:

- Highly efficient production with fast turnaround, and an on-time delivery rate of over 98%

- Superior scalability for low- to high-volume production runs

- Dedication to maintaining cost-effective services

- Specialized materials and presses for high mechanical strength and precision

- Value-added capabilities, including finishing, assembly, and packaging

Injection Molding Services From D&M Plastics

When you trust D&M Plastics for injection molding and other services, you’ll benefit from top-tier manufacturing that meets your needs. Our entire team is committed to customer service and providing quality components as you need them, when you need them.

Contact us today for more information, or request a quote to start your custom injection molding project.